SIGNA - Millions of possibilities

What is Signa?

Signa consists of a weather-resistant Rockpanel® and a composition of Vandersanden brick slips which is adhesively bonded.

The panels are produced for you ready-to-use, which can give your projects a unique and striking look.

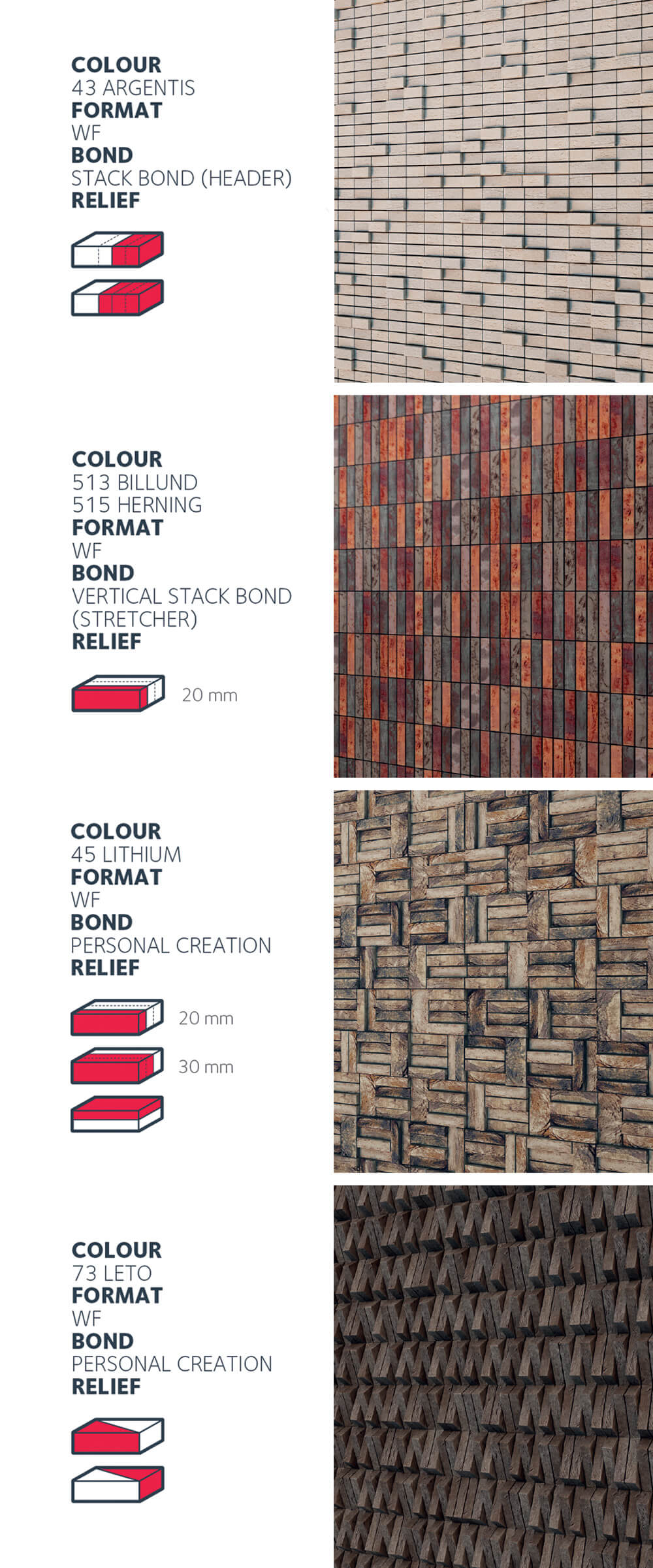

Signa as an innovative facade cladding system gives a whole new dimension to brick as a facade cladding. It offers many possibilities for exclusive projects, high-rise buildings or other architectural projects. You can play with relief, colour, format, brickwork bond and create your own design with expressive facades that fully highlight the character of brick.

Thanks to Signa, you can get either robust or elegantly irregular full-relief facade, entirely according to your individual design with Vertical, horizontal or diagonal patterns.

Technical Characteristics

Rockpanel®

The supporting panel on which the brick slips are adhesively bonded in the factory is a form-retaining and weather-resistant Rockpanel® board composed of compressed and solidified basalt rock fibres. The format is variable and can be optimally harmonised with your project.

Vandersanden brick slips

For the brick slips you can select any brick from the Vandersanden line. This is regardless of format, colour or direction of saw cut – even diagonally cut is possible. You also possess an un-precedented degree of freedom with regard to brickwork bonds, combinations of types of brick, repetition of patterns or gradual colour and/or format variation over the whole of the facade. You choose the composition and the variations in the relief yourself.

Millions of possibilities

On the basis of four variables Signa gives endless patterns.

Colour

You choose and combine from the full Vandersanden line. We offer you a range of more than one hundred colours, expanded by the four surface textures: hand-moulded, formback, water-struck and aged.

Relief

We can cut slips of various thicknesses for the stretcher, the header and the sole. You choose a straight or diagonal cutting line. Moreover, several parts can be used from one and the same brick. You do not have to limit yourself to just a single cutting line. By combining several cutting lines you create an intense composition with a varying relief that is full of character.

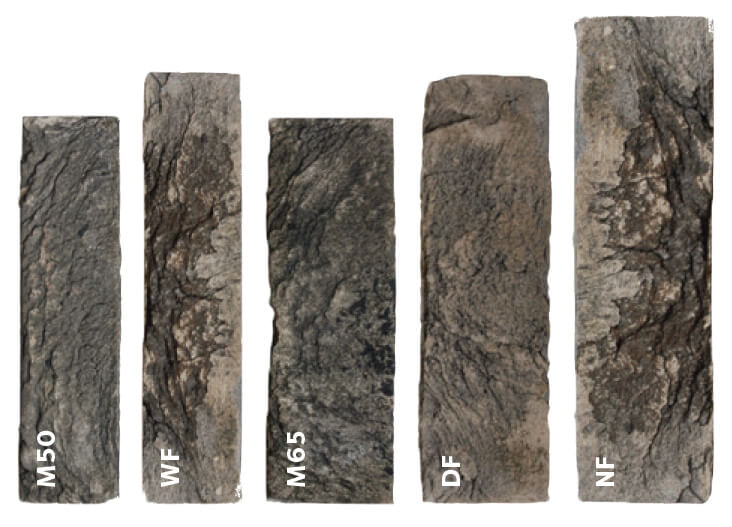

Format

As a basis you can use the stretcher, header and slip of five Vandersanden brick formats:

M50 ± 190 x 90 x 50 mm

WF ± 210 x 100 x 50 mm

M65 ± 190 x 90 x 65 mm

DF ± 210 x 100 x 65 mm

NF ± 240 x 115 x 70 mm

Bond

You can apply the familiar brickwork bonds such as half-brick, English bond or irregular bond. Combinations of these brickwork bonds are achievable. Horizontal, vertical and even diagonal brick sections are amongst the possibilities. This is feasible because Signa is not laid but adhesively bonded, thus offering greater freedom.

From design to implementation

1. You work out a unique patternof brick slips. 2. We discuss with you the possibilities of the designed composition and work out a three-dimensional visualisation of the panel. 3. The mounting method is determined. 4. The facade plan is fully elaborated in detail. 5. After approval, the Signa panels go into production. 6. The Vandersanden Group transports the panels safely and punctually to the work site. 7. A specialised installation company fastens the Signa panels at the building site.

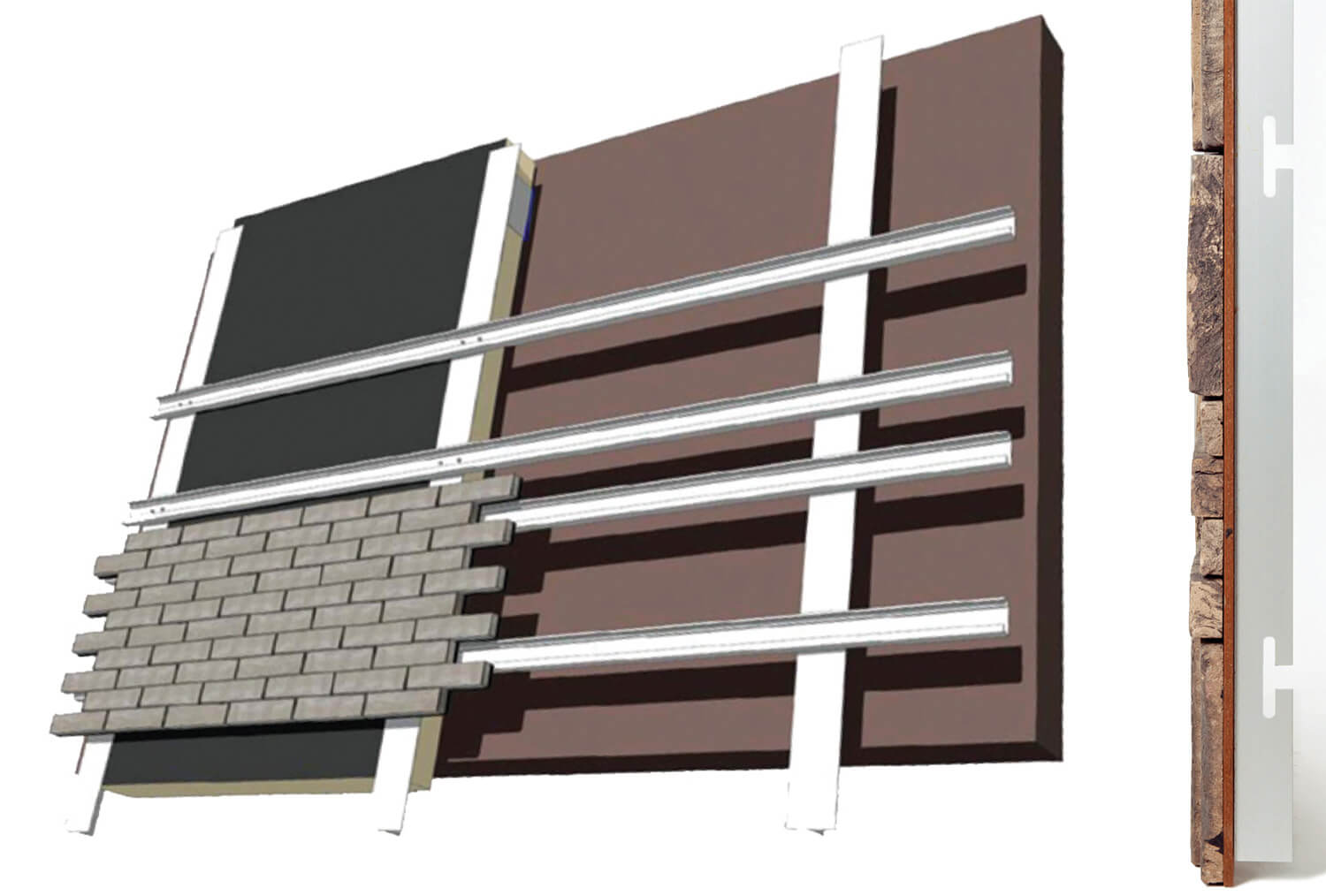

Mounting

The ready-to-use Signa panel can be mounted in several ways.

Screw or glue Signa onto an aluminium or wood framework. This framework can be mounted on a range of different substrates.

Aluminium support structure

The posts of the aluminium support structure are mounted against the bearing wall. In new construction this the inner cavity wall, in renovations the existing facade. After installation of, preferably black coated, insulation between the vertical aluminium T-profiles, horizontal C-profiles are mounted. Specialised installation companies then fasten the Signa panels with aluminium plate hooks to the support structure.

Wooden support structure

The water-resistant spar work of a wooden support structure is built up in the same way as an aluminium support structure. The vertical posts are anchored to the rough structure with distance bolts so that insulation can be applied. Vertical laths at the level of the framework keep black vapour-permeable foil in its place. With both installation systems, the individual mounting of fitting pieces ensures that the separate Signa panels harmoniously merge into a single whole.